Vaughan

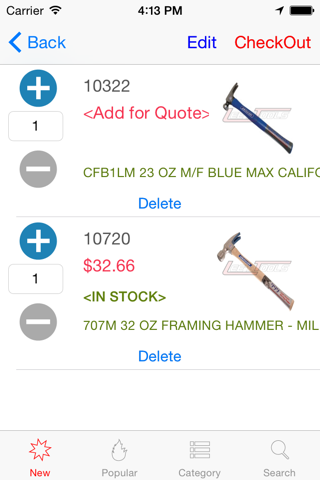

999, California Framer, Blue Max, V Series, Steel Eagle, SuperBar

Bear Saw Hand Saws, Curved Claw Hammers, Contractor and Tradesman, Hatchets & Axes, Industrial Tools, Straight Claw Hammers, Superbar & Pry Bar, Soft Face Hammers, Ti-Tech Titanium Hammers, Replacement Handles

Weve been designing and manufacturing hammers for over 135 years. Many of what are now accepted as basic hammer designs - from the distinctive curve of the claw to the set of the handle and the shape of the head - were introduced by Vaughan. All are the result of Vaughans commitment to constant hammer improvement and extensive field testing.

Balance

Balance is difficult to describe and impossible to formulate, but when a hammers got it - you can just "feel it." A well-balanced hammer can seem to "swing itself" reducing stress on muscles and tendons. The hammer becomes an extension of arm, swinging smoothly and easily, delivering power blows almost effortlessly. Of course, not all hammers have the same feel. Obviously, a 10 oz. finishing hammer feels different than, say, a 24 oz. framer. Proper head-to-handle weight distribution is one of the key factors and Vaughan hammers have it!

All Vaughan hammers are designed with our exclusive CAD/CAM system and extensively field tested, with special attention to the balance that has made Vaughan the choice of the pros.

Heat Treating

The single most important procedure in the manufacture of a Vaughan hammer is controlling the temper or degree of hardness of the head. Of course, its important to start with the right steel. Vaughan uses only U.S. made, high carbon steel. Correct hardening is achieved by the very precise process called heat treating. Vaughan hammers are "triple zone" heat treated, ensuring that the striking face, claws and eye each have precisely the right hardness and toughness for the different jobs they must do.

The depth of the hardening on the striking face is just as important as the degree of hardness. Unfortunately, since hardness cannot be seen, it is often neglected, affecting the hammers durability and making it a potentially dangerous tool. When the striking face is too soft, or hardness to shallow, the face can mushroom. If its too hard it becomes brittle and chips easily. Vaughan hammers are deep hardened, an extra step to make them more durable.

If the claws of a hammer were as hard as its face they could fracture under pulling forces, so we make our claws softer, but without losing toughness. Because the eye strength rather than hardness we make it even softer.

Correct Hardness for the Job

Claw hammers are hardened specifically to strike common (unhardened) nails, spikes and nail sets. They should never be used to strike hardened nails or tools such as cold chisels, punches or drills. Vaughan also manufactures hammers designed and specially hardened to handle these jobs.